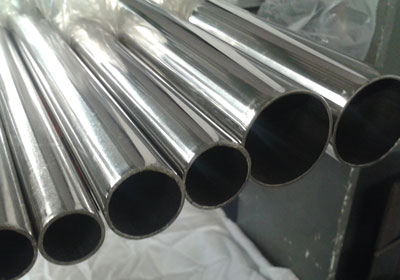

Alloy 20 Pipe manufacturer, ASTM B729 Alloy 20 welded Tubes exporter, Incoloy® alloy 20 Welded Pipe, Carpenter 20 Seamless Tube supplier, Alloy 20 Pipe exporter in worldwide.

- ASTM B729 Incoloy® alloy 20 Pipes

- Alloy 20 ERW Tubes

- Carpenter 20 Seamless Piping

- ASTM B729 Alloy 20 Tubing

- 20Cb-3® Round Pipe

- Alloy 20 EFW Tubes

- Alloy 20 Welded Pipe

- Carpenter 20 Tube Exporter

- 20Cb-3® Rectangular Pipe

- Carpenter 20 Polished Tubes

- ASTM B729 Alloy 20 Thin Wall Pipes

- Alloy 20 Tube Supplier

Alloy 20 Pipes, ASTM B729 / SB729 Carpenter 20 Welded Tubes manufacturer, ASTM B729 Alloy 20 Pipe Prices, Incoloy® alloy 20 Tube Specification, ASTM B729 Alloy 20 Seamless Tubes Supplier in Mumbai.

Norwich Steel & Engineering Co. is one of the well-known manufacturers of Alloy 20 Pipes and Tubes, which is readily fabricated by usual industrial processes. Alloy 20 Seamless Pipes is often chosen to solve stress corrosion cracking problems. Alloy 20 Welded Tubes excels in resisting corrosion to hot sulfuric acids. Welding of Alloy 20 EFW Pipes is commonly performed via MIG, TIG, as well as SAW by using the matching filler metal. Alloy 20 ERW Tube as well has excellent mechanical characteristics at ambient and high temperatures. Alloy 20 Round Pipes has chloride stress corrosion cracking resistance. Niobium stabilisation allows Alloy 20 Square Tubes to be used in corrosion environments in the as welded condition. Alloy 20 Rectangular Pipes may only be hardened by cold work. By means of easy manufacture and high mechanical properties, Alloy 20 Electropolish Tubes as well offers outstanding erosion resistance.