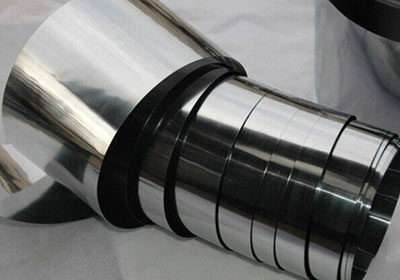

Incoloy® alloy 20 Coils, Carpenter 20 Chequer (Floor) Sheets, Alloy 20 Mill Finished Sheets Manufacturer, Carpenter 20 8 Finish Sheets, 20Cb-3® Polished Finishes Sheets & Plates, Carpenter 20 2B Finish Plates, Alloy 20 Embossed Sheets Exporter in Worldwide.

- ASME SB 463 Alloy 20 Strips

- Carpenter 20 Foils

- Incoloy® alloy 20 Chequered Plate

- 20Cb-3® Hot Rolled Plates

- ASTM B 463 Carpenter 20 Cold Rolled Plates

- Alloy 20 Coils Exporter

- Carpenter 20 Chequer (Floor) Sheets

- 20Cb-3® Slit Coils

- Incoloy® alloy 20 Sheets, Plates, Coils

- ASTM B 463 Carpenter 20 Perforated Sheet

- 20Cb-3® Polished Plates

- Carpenter 20 Coils

Alloy 20 Blanks, Rings, Strips, ASTM B 463 Alloy 20 Foils, Incoloy® alloy 20 Bright Annealed Finish Coil, Carpenter 20 Chequered Plate manufacturer, Foils, Exporter, ASME SB 463 Alloy 20 Shim Sheets Manufacturer, Circles, 20Cb-3® Flats exporter in worldwide.

Norwich Steel & Engineering Co. is one of the well-known stockist of Alloy 20 Sheets Plates and Coils, which is originally designed for use in sulfuric acid related industries. Low heat input is necessary in our Alloy 20 Plates, where the interpass temperature should not exceed 120 °C (250 °F). These Alloy 20 Coils has outstanding confrontation to hot sulfuric acid and a lot of other hostile atmospheres that would outbreak Alloy 316. The nickel content of our Alloy 20 Perforated Sheets aids in its chloride ion stress and corrosion resistance. These Alloy 20 Perforated Plates is also stabilized with Columbium to minimize carbide precipitation during welding. Hot forged material should be heated between 2100 °F and 2250 °F with careful temperature control insuring that our Alloy 20 Perforated Coils not fall below 1800 °F prior to forging. Constrained carbon induced columbium steadiness in these Alloy 20 Slatting Sheets allows welded productions to be utilized in corrosive atmospheres, usually deprived of post - weld heat action.