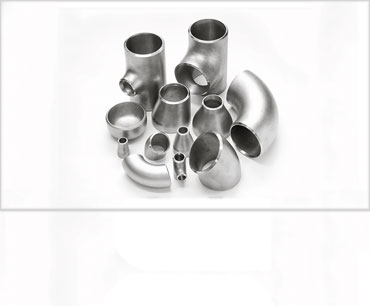

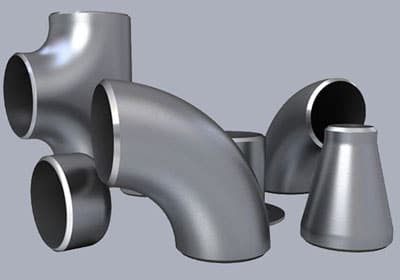

SS 304H Welded Pipe Fittings, SS 304H Stub Ends Suppliers, Stainless Steel 304H Equal Tee, India's Largest Manufacturer of Best Quality Stainless Steel 304H Pipe Fittings, SS UNS S30409 Seamless Pipe Fittings, ASME B16.9 SS 304H Seamless Pipe Fittings Exporter in Worldwide.

- Stainless Steel 304H Butt weld 90 deg Elbow

- SS WERKSTOFF NR. 1.4301 Cross

- Stainless Steel 304H Reducer

- ASTM A403 SS 304H Swage Nipple

- Stainless Steel 304H Buttweld Fitting

- ASME B16.28 SS 304H Pipe Fitting

- ANSI B16.9 Stainless Steel 304H End Pipe Cap

- SS 304H Welded Pipe Fittings Exporter

- Stainless Steel 304H Buttweld 90 deg. Elbow

- UNS S30409 Welded Pipe Fitting Exporter

- SS 304H Long / Short Radius Elbow

- Stainless Steel 304H Pipe Fitting

Stainless Steel 304H Pipe Fitting Price List, ASME B16.28 SS 304H Pipe Fittings manufacturer, Stainless Steel 304H 45 Degree Elbow, ANSI B16.9 SS 304H End Pipe Cap Manufacturer, Manufacturers of SS WERKSTOFF NR. 1.4301 Buttweld Fitting exporter in worldwide.

After cold forming (work hardening) and after welding (risk of inter-granular corrosion in the weld joint) in Stainless Steel 304H Butt Weld Fittings, an annealing treatment for a couple of minutes followed by air cooling restores the microstructure (re-crystallization and dissolution of carbides) and eliminates internal stresses. Heavy section welding in Stainless Steel 304H Elbow is required and post-weld heat treatment is not possible. SS 304H Teemay be required for full corrosion resistance when thicker sections are welded. As the most widely and versatile used among all alloys, the mechanical attributes and chemical composition of Stainless Steel 304H Reducer offer the finest all-around show at comparatively lower cost. SS 304H Cross has higher strength at elevated temperatures. Assessment of these parameters in Stainless Steel 304H Bend and accurate prediction of the probability of SCC occurring in service is therefore difficult. Our Stainless Steel 304H Stub End cannot be hardened by thermal treatment.