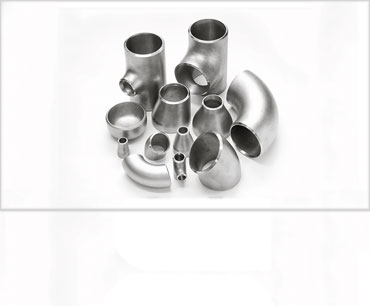

ASME B16.9 SS 904L Seamless Pipe Fittings, SS 904L Welded Pipe Fittings, India's Largest Manufacturer of Best Quality Stainless Steel 904L Pipe Fittings, SS 904L Stub Ends Suppliers, SS UNS N08904 Seamless Pipe Fittings, Stainless Steel 904L Equal Tee Exporter in Worldwide.

- ASME B16.28 SS 904L Pipe Fitting

- Stainless Steel 904L Butt weld 90 deg Elbow

- SS WERKSTOFF NR. 1.4539 Cross

- Stainless Steel 904L Reducer

- ASTM A403 SS 904L Swage Nipple

- Stainless Steel 904L Buttweld Fitting

- Stainless Steel 904L Pipe Fitting

- ANSI B16.9 Stainless Steel 904L End Pipe Cap

- SS 904L Welded Pipe Fittings Exporter

- Stainless Steel 904L Buttweld 90 deg. Elbow

- UNS N08904 Welded Pipe Fitting Exporter

- SS 904L Long / Short Radius Elbow

ANSI B16.9 SS 904L End Pipe Cap Manufacturer, Stainless Steel 904L Pipe Fitting Price List, ASME B16.28 SS 904L Pipe Fittings manufacturer, Stainless Steel 904L 45 Degree Elbow, Manufacturers of SS WERKSTOFF NR. 1.4539 Buttweld Fitting exporter in worldwide.

Depending on the customer's end-use requirements, cutlery alloys such as these Stainless Steel 904L End Cap are usually selected with respect to heat treating response, mechanical properties and fabricating characteristics. While Stainless Steel 904L Stub End can be machined in the annealed condition, it tends to perform better in the cold drawn or heat treated condition. For solution annealing in SS 904L Bend, slow controlled cooling from 1500 Degree F / 1600 Degree F, and for hardening, heat up to 1700 Degree F / 1850 Degree F, further quench in air or oil. For maximum corrosion resistance to chemical environments, SS 904L Reducer is essential that the stainless steel surface be free of all heat tints or oxide formed during forging, annealing, or heat treating. Applications requiring moderate corrosion resistance and high mechanical properties are ideal for this Stainless Steel 904L Cross.