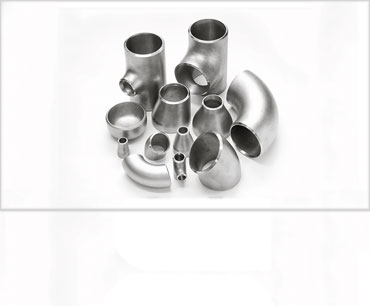

Stainless Steel 310S 45 Degree Elbow, Manufacturers of SS WERKSTOFF NR. 1.4845 Pipe Fitting Price List, ASME B16.28 SS 310S Pipe Fittings manufacturer, ANSI B16.9 SS 310S End Pipe Cap Manufacturer, Stainless Steel 310S Pipe Fitting exporter in Mumbai.

- Stainless Steel 310S Buttweld 90 deg. Elbow

- ASTM A403 SS 310S Pipe Fitting Exporter

- SS 310S Long / Short Radius Elbow

- Stainless Steel 310S Pipe Fitting

- SS WERKSTOFF NR. 1.4845 Pipe Fitting

- SS 310S Welded Pipe Fittings Exporter

- Stainless Steel 310S Reducer

- UNS S31008 Seamless Pipe Fittings,

- Stainless Steel 310S Buttweld Fitting

- ASME B16.28 SS 310S Pipe Fitting

- Stainless Steel 310S Butt weld 90 deg Elbow

- Stainless Steel 310S Cross

SS 310S Stub Ends Suppliers, SS 310S Welded Pipe Fittings, India's Largest Manufacturer of Best Quality Stainless Steel 310S Pipe Fittings, ASME B16.9 SS 310S Seamless Pipe Fittings, Stainless Steel 310S Reducer, UNS S31008 Welded Pipe Fittings Exporter in Worldwide.

Stainless Steel 310S Butt Weld Fittings is readily fabricated by standard commercial procedures. Stainless Steel 310S Elbowfinds wide application in all high-temperature environments where high temperature strength and good creep resistance are required. Stainless Steel 310S Tee is austenitic chromium – nickel alloy steel with high strength and excellent corrosion resistance. Stainless Steel 310S Cross may have a carbon content which will not be acceptable for some high temperature applications. Stainless Steel 310S Reducer has excellent resistance to hot corrosion. SS 310S Bend is not prone to thermal fatigue and cyclic heating. Full annealing of Stainless Steel 310S Stub End is required after cold work to remove internal stress. Stainless Steel 310S End Cap is quite ductile and forms in a manner very similar to Stainless Steel 316 Pipe Fittings. Pickling and passivation of the surface in Stainless Steel 310S Dish Cap to remove high temperature oxides are essential to restore full aqueous corrosion resistance after welding.