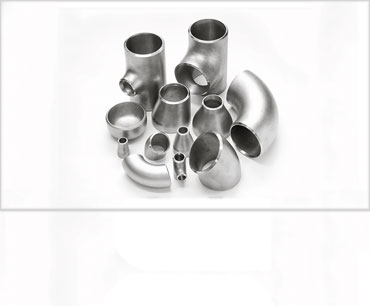

Stainless Steel 316 Pipe Fitting, ASME B16.28 SS 316 Pipe Fittings manufacturer, Manufacturers of SS WERKSTOFF NR. 1.4401 / 1.4436 Pipe Fitting Price List, ANSI B16.9 SS 316 End Pipe Cap Manufacturer, Stainless Steel 316 45 Degree Elbow exporter in Mumbai.

- Stainless Steel 316 Pipe Fitting

- SS WERKSTOFF NR. 1.4401 / 1.4436 Pipe Fitting

- SS 316 Welded Pipe Fittings Exporter

- Stainless Steel 316 Buttweld 90 deg. Elbow

- ASTM A403 SS 316 Pipe Fitting Exporter

- SS 316 Long / Short Radius Elbow

- ASME B16.28 SS 316 Pipe Fitting

- Stainless Steel 316 Butt weld 90 deg Elbow

- Stainless Steel 316 Cross

- Stainless Steel 316 Reducer

- UNS S31600 Seamless Pipe Fittings,

- Stainless Steel 316 Buttweld Fitting

SS 316 Welded Pipe Fittings, India's Largest Manufacturer of Best Quality Stainless Steel 316 Pipe Fittings, SS 316 Stub Ends Suppliers, UNS S31600 Welded Pipe Fittings, ASME B16.9 SS 316 Seamless Pipe Fittings, Stainless Steel 316 Reducer Exporter in Worldwide.

Stainless Steel 316 Butt Weld Fittings can be worth the expense if you need to have superior corrosion resistance. SS 316 Elbow makes them ideal for chemical resistant and salt water applications, as well as having the condensed, light and commanding features. Heavy welded sections in Stainless Steel 316 Tee may require post-weld annealing. Unfortunately, concentrations of chloride in seawater can vary, and splash zones can cause concentrations to increase dramatically by evaporation in Stainless Steel 316 Reducer, thus the corrosive severity of marine environments can vary. A color develops as a result of a chemical reaction and, generally, the intensity of the color in Stainless Steel 316 Cross can be used to estimate the amount of alloying component present. Stainless Steel 316 Stub End has excellent weldability by all standard fusion methods, both with and without filler metals. Stainless Steel 316 Bend is suitable for welding because it has carbon content to avoid carbide precipitation in welding applications.